These three fundamentals are just the beginning of course.

Mazak laser cut conditions.

North american headquarters are located in elgin illinois and feature a 30 000 sq.

North american headquarters are located in elgin illinois and feature a 30 000 sq.

A foundation for solid cutting conditions.

Cutting conditions database optimum cutting conditions including cutting speed.

The previewg advantage optiplex nexus 3015 fiber.

In laser cutting how the laser beam assist gas and material interact determines the quality of cut.

The revolutionary mazatrol cnc developed exclusively by mazak was first used on metal cutting machine tools in 1981.

Fine power ramping function controls laser output and feedrate optimum cutting conditions are automatically used for high speed straight and corner cutting to prevent dross.

In his book using a co 2 laser in the shop david marusa describes optimum cutting conditions with a bowl metaphor.

Mazak optonics corporation is a major supplier of laser cutting systems offering 50 laser models and leading the industry in the implementation of emerging laser technologies.

The company s 50 000 sq.

Laser technology center housing up to 18 machines.

The company s 50 000 sq.

Applying different cutting conditions speeds automatically.

Smaller features may need to use the medium condition to minimize heat buildup when cutting.

But these at least provide a starting point to develop finely tuned cutting conditions which can vary depending on a host of environmental factors such as.

After slowing down and changing the assist gas pressure to accommodate the operator finds an even larger burr.

Here dross forms as molten material solidifies before it can be evacuated from the kerf.

Shops may need to look into factors like shielding gas flow or adding extra protection to the beam delivery optics in the co 2 system.

Laser technology center housing up to 18 machines.

Often when laser cutting not all features can be cut utilizing the same cutting condition.

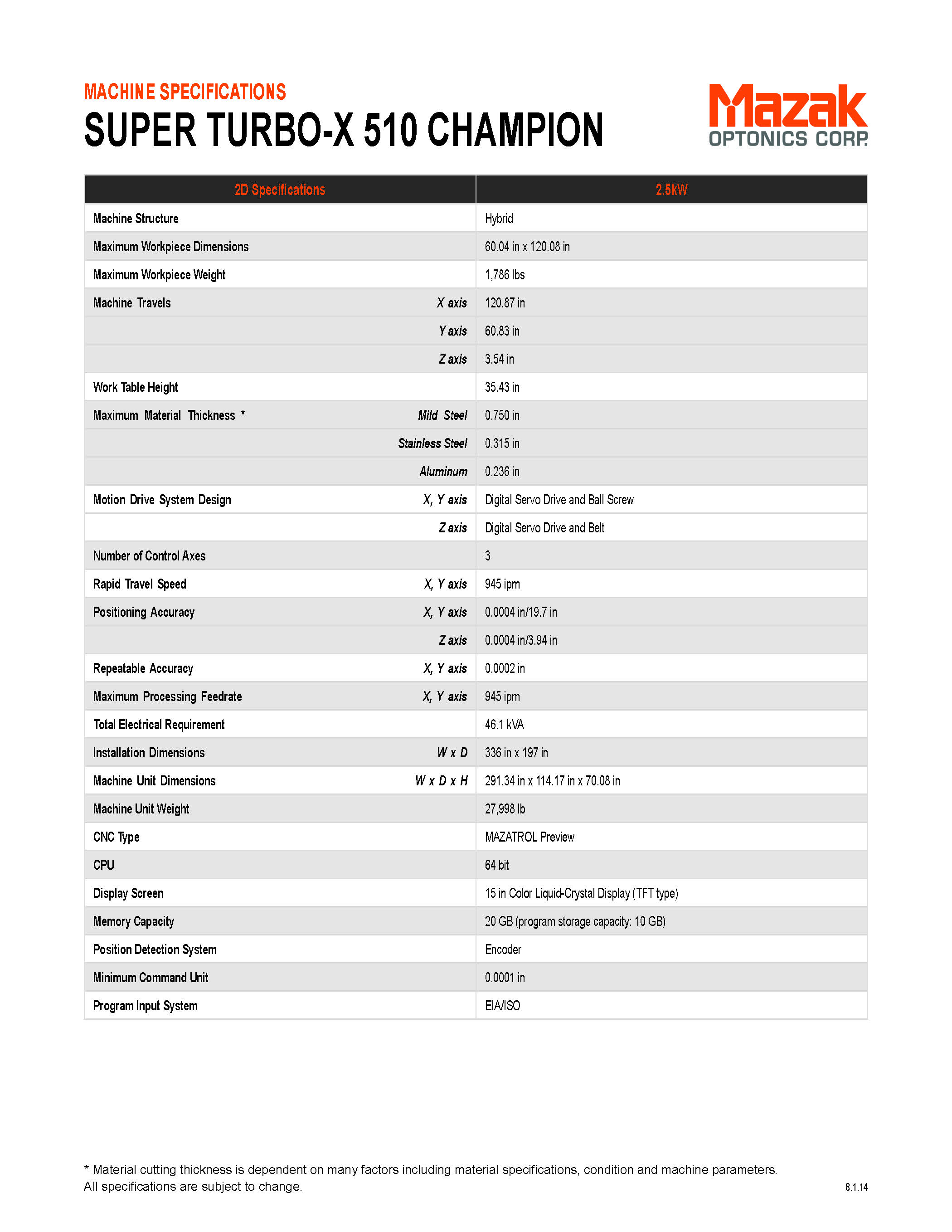

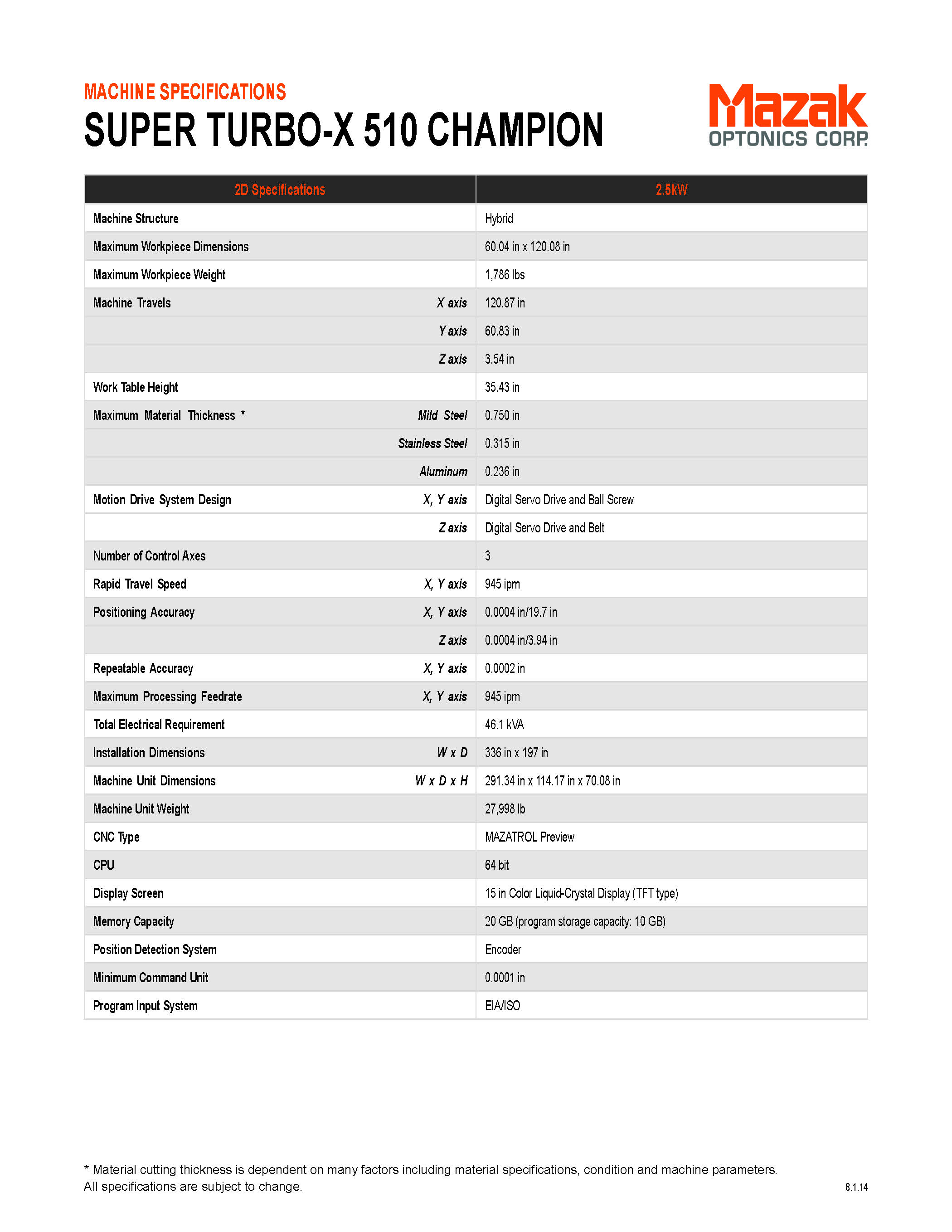

Mazak laser processing machine cnc systems.

With all parameters tuned for the material and thickness at hand including feed.

This can be configured automatically in the mazak smart system software.

Equipped with mazak s intelligent functions rugged construction and now the mazatrol previewg control offering outstanding value.

Mazak optonics corporation is a major supplier of laser cutting systems offering 50 laser models and leading the industry in the implementation of emerging laser technologies.

Open nest and.

Automatic functions incorporating mazak s expertise accumulated over many years that ensure high quality and high efficiency laser cutting.

The optiplex nexus fiber is an affordable solution that delivers cutting edge technology.